Introduction to the Indian Construction Industry

India’s construction industry is among the best in the world, offering an immense contribution to the economy and job opportunities. There is a rising demand for advanced construction machinery ranging from urban infrastructure, housing projects, road construction, to smart cities. This development focuses on safety, speed, and precision— all of which depend heavily on construction equipment manufacturers. Why choose Jaypee India Limited?

Why Choosing the Right Construction Equipment Manufacturer Matters

Construction requires a significant investment of resources, is time-sensitive, and heavily relies on machinery. Any delays resulted from subpar equipment, services, or repairs can ground entire projects to a halt. That’s why successful builders and contractors seek out the leading construction equipment manufacturer in India — a partner who ensures:

- Reliable machinery

- Timely delivery

- Customization

- Post-sales service

- Cost-effective performance

Meet the Leading Construction Equipment Manufacturer in India

Company History and Reputation

Over 42+ years ago, Jaypee India Limited commenced operations as one of the pioneers in the manufacturing of world-class construction equipment. As an Original Equipment Manufacturer (OEM), Jaypee® is a trusted brand among construction companies, infrastructure developers, and government agencies across the nation.

Types of Equipment Offered

Jaypee® offers a wide range of high-performance equipment, including:

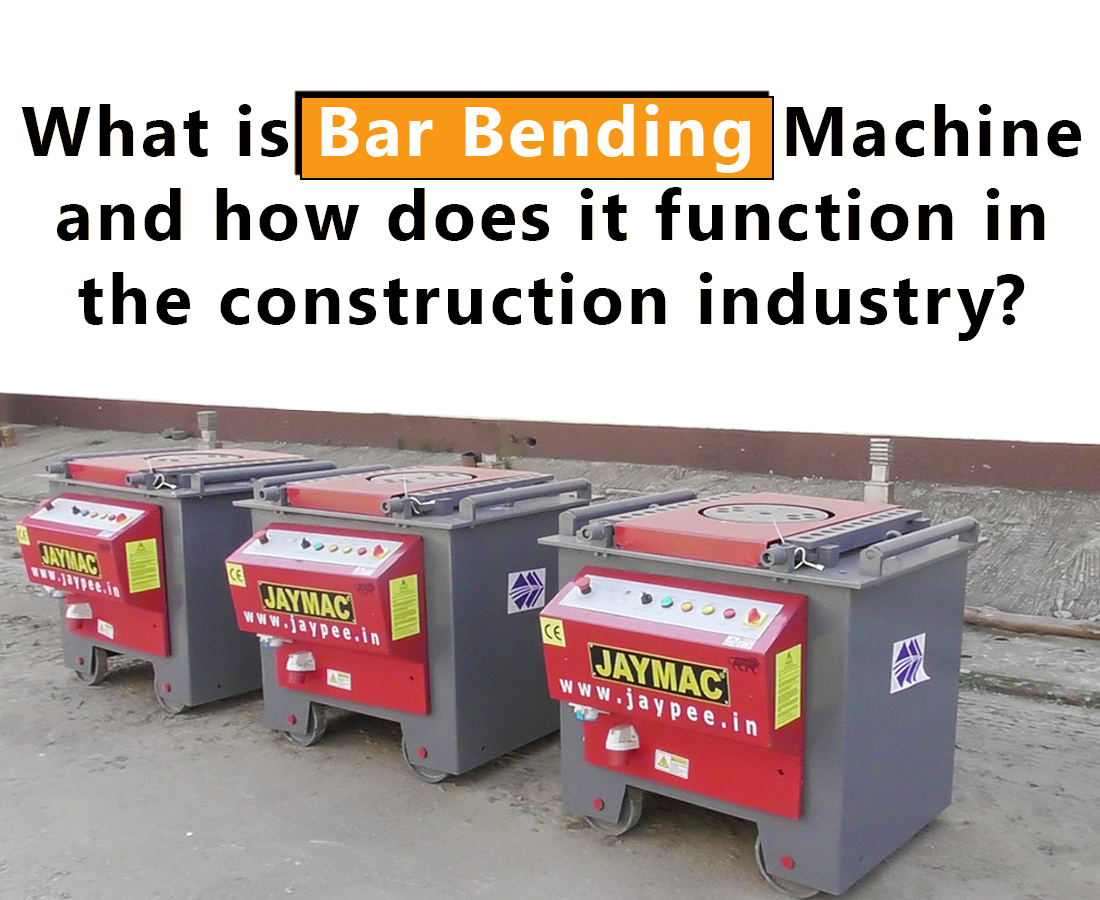

- Bar Bending Machines

- Bar Cutting Machines

- Concrete Mixers (Reversible Drum)

- Walk-Behind Rollers

- Material Hoists

- Passenger Hoists, etc

Each product is thoughtfully engineered to perform reliably under challenging site conditions, ensure high productivity, and minimize maintenance requirements.

Quality Standards and Certifications

We hold ISO certification, which signifies compliance with both international and Indian standards, including ISI. Safety, reliability, and performance are tested for each product along with quality testing which has to pass industry standards.

7 Reasons Why Top Builders Trust This Manufacturer

1. Unmatched Reliability and Durability

Our equipment is structural perfection oud using state-of-the-art technology and top tier raw materials. Each machine is put through real life scenario tests to evaluate their stress response.

2. Timely Delivery of Products

In our wide distribution network and regional warehouses across the country, Jaypee® makes sure your equipment arrives on time—because we understand how important deadlines and commitments are in the construction business.

3. Customization Options Available

Every construction site has its unique challenges. We offer tailored solutions regarding voltage, size, material handling and any special feature requirements to streamline contractors’ productivity.

4. Dedicated After-Sales Service and Support

A responsive support system with trained service engineers, annual maintenance contracts (AMC), and readily available genuine spare parts ensures minimal downtime.

5. Cost-Effective Solutions for All Budgets

From small builders to mega-project developers, We maintain competitive pricing without sacrificing quality. Long-term savings stem from lower repairs and higher uptime.

6. Technological Advancements in Equipment Design

We integrate smart tech features such as:

-

Digital counters

-

Energy-efficient motors

-

Enhanced safety systems

-

IoT compatibility on select machines

This focus on innovation future-proofs your investment.

7. Positive Client Testimonials and Case Studies

Thousands of builders trust Jaypee®. Because we are a leading construction equipment manufacturer in India and testimonials from real estate developers, metro project contractors, and government clients praise the machine performance, durability, and service quality.

Case Studies: Real-Life Examples of Project Success

Metro Rail Project – Delhi

Jaypee®’s bar bending and cutting machines helped the contractor achieve 95% efficiency, reducing rework and equipment-related delays.

Residential High-Rise – Mumbai

Jaypee®’s reversible drum concrete mixer was used across 28 floors, with zero major faults reported during the entire 18-month construction period.

National Highway Project – Tamil Nadu

Material hoists and walk-behind rollers from Jaypee® enabled faster material movement, saving 2 weeks of project time.

Alternatives to Consider

While Jaypee India Limited is widely considered the leading construction equipment manufacturer in India, here are a few other names builders may explore:

-

Universal Construction Machinery – Specializes in concrete solutions

-

Safari Construction Equipment – Popular for mini batching plants

-

Kailash Engineering – Budget equipment for small contractors

However, these brands often lack OEM control, offer limited customization, or fall short in after-sales support — areas where Jaypee® clearly leads.

What Industry Experts Say

Real feedback from India’s top builders reflects the trust and satisfaction they have in Jaypee®’s machines and service.

“I am so satisfied using Jaypee Bar Cutting (C-42) & Bar Bending (B-42) machines. These machines are reliable and long-lasting. The service team is also very good.”

— Project Manager, Top Infrastructure Firm – Eastern India

“Technically sound and equipment supplied are of good quality standards. After-sales service is excellent. The entire team is technically sound.”

— Procurement Head, National Highway Contractor – South India

“This is to infrom that we have beeen using passenger cum material hoists manufactured by JAYPEE® for the past 10 years. The quality and realiablity of these hoists have consistently met our expectations and it contributed to successfully completion of serveral projects. The after sale service of the company is also appreciable which has further strengthended our trust in their products.

The responsive and supportive service team ensures a smooth and comfortable user experience, making JAYPEE® hoists a dependable choice for our operations.”

— General Manager, P S Group Realty Pvt. Ltd. – Kolkata

“We’ve been using passenger hoists from JAYPEE® for the past 6 months, and our experience has been consistently positive. The quality, performance, and reliability of their hoists have played a key role in the successful execution of several projects.

What truly sets Jaypee India Limited apart is their excellent after sales service. Their responsive and supportive service team ensures minimal downtime and a smooth user experience. This level of commitment has strengthened our trust in both the brand and its products.”

— Procurement Head, DTC Projects Pvt. Ltd. – Kolkata

Conclusion: Build Better with India’s Trusted Manufacturer

If you’re looking to deliver quality construction work, the machines you use matter. We provide:

- Durable OEM-quality machinery

- Nationwide support & fast delivery

- Custom solutions and innovation

Don’t compromise your project’s success with subpar equipment. Choose the leading construction equipment manufacturer in India and partner with a brand that top builders already trust.