India is becoming a global leader in the manufacturing sector and, probably, in no other sector is this more visible than in the construction equipment sector. As the country’s infrastructural development continues with renewed intensity, the need for quality construction equipment has surged. This situation has provided India with the construction equipment manufacturing capability, and is, therefore, highly ranked among the other construction equipment manufacturing nations. Why Choose Jaypee India Limited?

Such a situation does not occur by chance. It is a product of a unique combination of government policy, a motivated and competitive workforce, and a combination of favorable economic conditions. To global manufacturers wanting to increase the pie of their production, or Indian manufacturers wanting to scale up their production, India presents an interesting proposition of the aircraft production of the nation with major emphasis on the production of the large construction equipment and the production of the smaller construction equipment.

In this article, we will address the key variables that have enabled India to become a leading construction equipment manufacturer in the world. We will analyze the factors of the facilitating policies of the governments, the presence of educated and trained workforce, the low cost of conducting business, and the strong domestic market, and these factors have come together to form an exceptional manufacturing environment. Such knowledge of the factors is important for anyone wanting to enter the market or to expand in the market.

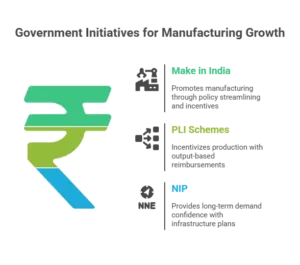

Government Support and Favorable Policies

Favorable government policies have made a positive impact on the manufacturing progress made by the country. The “Make in India” initiative has encouraged the country to become a global manufacturing hub. The global and domestic players in the market have been encouraged to be a part of India’s manufacturing scene by providing them with a positive business environment.

Important Initiatives by the Government

- Make in India: This initiative intends to promote and grow the manufacturing sector in India. The initiative streamlines policies, enhances facilities, and offers tax holidays and other benefits to companies that establish manufacturing facilities in India. This initiative allows manufacturers of construction equipment to experience lower bureaucratic processes and gain easier a desert in land and other construction.

- Production-Linked Incentive (PLI) Schemes: The government has initiated the “Production Linked Incentives” programs in overs 20 sectors, including automotive and heavy machinery. Under these programs, companies are reimbursed on the basis of the manufacturing output produced, thus incentivizing them to grow the industry with their manufacturing capabilities in India.

- National Infrastructure Pipeline (NIP): The National Infrastructure Pipeline has been allocated over $1.4trillion worth of funding and has drawn out significant plans to be rolled out. With these plans in place, construction equipment manufacturers are provided with the long-term confidence in demand that has been lacking in the market.

India’s steady and predictable policies also incentivize risk tempered investments owing to reduced risk margins for potential investors. Hence, India becomes an attractive opportunity for many tier one construction equipment manufacturers aiming to globalize.

Cost-Effective Manufacturing

One of the primary benefits of making construction equipment manufacturer in India is the immense cost benefits. India provides lower operational and labor cost advantages than a good number of Western countries and even other manufacturing location in Asia.

Breakdown of Cost Advantages

- Labor Cost: India has a large and cheap workforce. Although there is a gradual increase in the cost of labor, the cost of labor will still be considered cheap when looked at from a global perspective. This means that the skill and productivity levels of the workforce will remain at the same level as the industry standards. There will be high quality equipment at lower prices.

- Raw Material: India has a lot of heavy machinery construction equipment and even iron ore and steel which are the major components of the construction equipment. When the construction equipment is manufactured, there will be a lot of these materials. This means there will be lower transport expenses clear.

- Administrative and other operational expenses: India provides lower costs when it comes to setting up a manufacturing plant (for example in terms of land and utilities). This means that these companies will have a lower cost and the other resources can be used to improve other efforts like technology, research and even development.

These factors of production will empower India as a main producer, which will allow these companies to meet the market needs at lower prices.

A Skilled and Abundant Workforce

One of the most valuable features of the Indian economy is the demographic dividend arising from the large, young, and growing population of the country. Each year, the country also produces large numbers of engineers, technicians and skilled workers. Such a large and versatile pool of human resources is particularly beneficial for the construction equipment manufacturing industry, which has specialized and sophisticated requirements.

Preparing a Future-Ready Workforce

Both the Indian Government and the private sector are contributing to the building of the construction equipment workforce. Many industry-oriented vocational training institutes and technical training colleges have been established, focusing on training in modern technologies and advanced construction equipment components, which include advanced welding, CNC machining and hydraulic systems, in order to equip the workers to manufacture modern, technological construction equipment.

For a construction equipment manufacturer in India, this is good news, as the country has a large pool of workers who can readily learn and master new technologies and manufacturing processes. The construction equipment manufacturing industry is also supported by a culture of continuous learning and upskilling, which enables the industry to meet and even exceed the requirements of different countries in terms of quality and innovation.

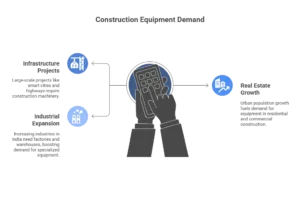

Growing Domestic Demand

The Indian construction industry is enjoying growth as a result of rapid urbanization, infrastructural development, and economic growth. It creates an enormous and dependable home market for construction equipment, thus providing a strong base for construction equipment manufacturers.

Drivers of Domestic Demand

- Infrastructure Projects: The Developing smart cities, highways, airports, and ports are large-scale projects that will require construction machinery. The demand will constantly be there as there is an unrelenting focus on infrastructure development.

- Real Estate Growth: The urban population is growing, and as a result, the expansion of the residential real estate and commercial real estate is fueling demand for construction equipment that serves building construction, earth-moving, and concrete pouring activities.

- Industrial Expansion: The Demand for specialized construction equipment is bolstered by the increasing number of industries establishing operations in India as it requires the construction of factories, warehouses, and industrial parks.

The strong domestic market in India enables construction equipment manufacturers to achieve a high scale of operations and lower their exports. It enables them to establish a diversified and large market for construction equipment, which allows them to experiment more and develop innovations from new products for the global market.

Charting a Course for Future Growth

India’s journey to becoming a leading construction equipment manufacturer is a testament to its strategic advantages and immense potential. The combination of supportive government policies, a skilled and cost-effective workforce, and robust domestic demand creates an ecosystem ripe for growth and innovation. 7 Reasons Why the Best Industrial Construction Company in India.

For businesses looking to capitalize on these opportunities, the path forward is clear. By leveraging the “Make in India” initiative and tapping into the country’s vast resources, manufacturers can build a competitive and sustainable operation. The future of construction equipment manufacturing is being shaped in India, and now is the time to be a part of it.

If you are looking to partner with a leading construction equipment manufacturer in India, exploring the landscape of established and emerging players can provide valuable insights into navigating this promising market.